Using extrusion technology, materials like plastics, metals, and food products are shaped and formed by pushing them through dies, enabling the production of diverse products with consistent shapes and sizes.

Solutions for

Extrusion

OVERVIEW

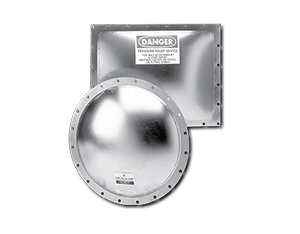

ZOOK offers rupture disks for extrusion barrels to prevent pressure build-up and ensure safety. They also provide rupture disks and vent panels for bulk storage applications, protecting against hazardous conditions caused by dust and static build-up in silos.

COMMON APPLICATIONS

Extrusion Barrel

The pressure inside the extruder barrel during the extrusion process is high, typically ranging between 1,000 and 15,000 psi. Excessive build-up of pressure could rupture the barrel and lead to major machine malfunction, costly downtime and operator safety issues. To protect the extruder barrel from over-pressurization, rupture disks (extrusion burst plugs) from ZOOK can be installed at (or near) the die end of the barrel.

Bulk Storage

Plastic pellets are the raw material used in the extrusion and thermoplastic blow molding processes. Typically stored in silos, the combination of dust vapors and static build up from pneumatic pellet transfer can create a hazardous condition. Rupture disks and vent panels from ZOOK provide relief from over-pressurization of the silo should ignition occur.

PRODUCTS BY APPLICATIONS

There are many other pressure relief applications we provide to the Extrusion Industry. Please contact ZOOK for applications not listed.

| Recommended Products | Extrusion Barrel | Bulk Storage |

|---|---|---|

|

Engineered to Order

|

||

|

Graphite Disks

|

||

|

Ultra-Low & Bi-Directional Disks

|

||

|

Plugs

|

||

|

Accessories

|

||

|

Explosion Vents

|

Applications List

Extrusion Barrel

Recommended Products

Bulk Storage

Recommended Products

Graphite Disks

Ultra-Low & Bi-Directional Disks

Accessories

Explosion Vents